Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur mattis neque consectetur, congue sapien quis, egestas magna. Fusce eget nulla vel dolor dictum aliquet. Duis urna diam, pellentesque non erat vel, finibus porttitor ex. Maecenas ac metus lacus. Nulla facilisi. Duis lorem mi, vestibulum ullamcorper ex a, iaculis vestibulum purus. Donec ultrices placerat turpis ut efficitur. Donec ut nisl pharetra, convallis diam a, ornare tellus. Pellentesque vel convallis dolor, id pellentesque augue. Cras neque nibh, cursus non erat nec, rutrum hendrerit turpis. Ut a lectus tincidunt, fringilla nibh non, consequat diam. Nam elementum semper malesuada. Ut efficitur purus in arcu ullamcorper, a bibendum est efficitur. Vivamus et nulla fermentum, vulputate sem vitae, ullamcorper est. Praesent consequat ante et ante fringilla, sit amet vehicula nisi rhoncus.

Digitalizing construction concrete quality control with industrial IoT and Azure

For construction companies, not knowing when the concrete is ready can cause operational delays down the line. But with our connected digital IoT solutions like the one Axelsson Consulting built for Thomas Concrete Group, a leading global producer and distributor of high-quality ready-mixed concrete to commercial and private customers, material readiness can be determined almost instantly, as well as providing a continuous snapshot of the historic and current state of the material in real-time, enabling new- and data-driven insights to the customers of the client that can greatly reduce waste, improve efficiency and shorten lead times at construction sites.

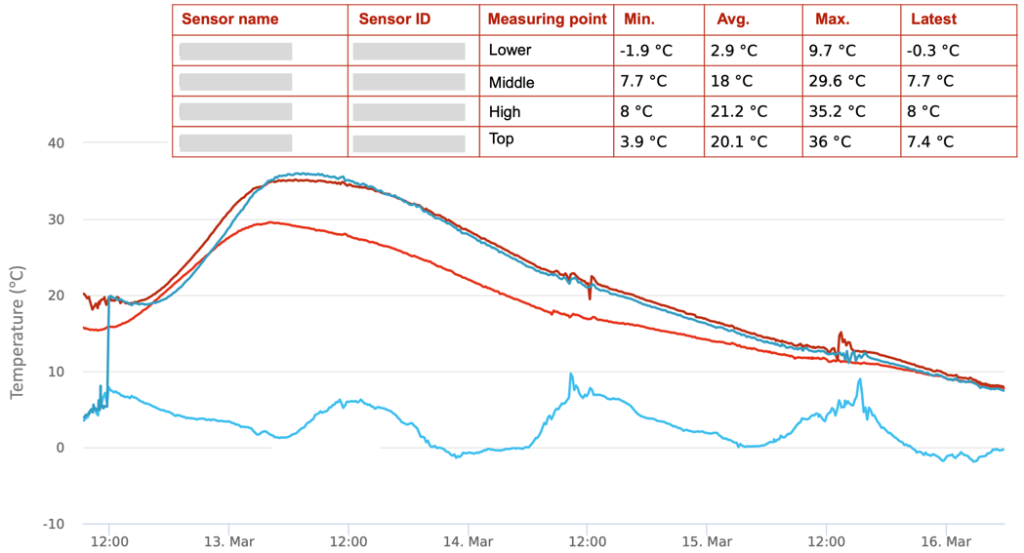

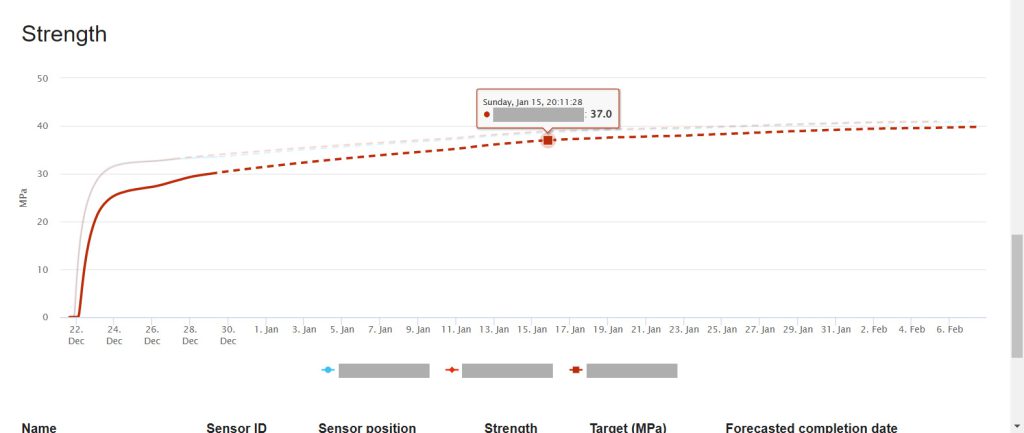

Concrete companies increasingly rely on digital solutions to make their operations more efficient, cost-effective, and customer friendly. With the help of IoT sensors, low-frequency network protocols, and the cloud, for example, they can provide customers with exact insights on when their concrete will be delivered and how strong the mix is, or is forecast to be, at any given time.

In this case study, we explore how our cloud-native IoT solution helped Thomas Concrete Group to gain a unique competitive advantage, by leveraging IoT sensors, IoT networks, and the full capabilities of the cloud, to extract the inherent value in sensor- and organization data to enable their customers to monitor concrete strength accurately, as easily as checking the weather.

The challenge: Efficiently measuring material strength

In the previous mode of operation, Thomas Concrete Group wasn’t able to provide customers with any meaningful insights about the properties of their concrete without extensive, and expensive, manual hands-on analysis and measurements, meaning that builders often waited longer than necessary to ensure that the material in the construction part was strong enough to meet safety thresholds. As an example, without accurate insights, builders would let the concrete cure until it reached a hardness of 46 or 47 megapascals, even though 40 MPa would be sufficient, resulting in unnecessary waiting time for each and every construction part, time that can add up to hours, days and even week during the course of a construction project, prolonging the overall project implementation time. Only then could they move on to the next phase of construction, such as adding another floor to a building.

A service was offered in the legacy mode of operation where data on material properties was collected, but it required a consultant to physically travel to each project construction site, manually place a sensor cable into the concrete connected to an offline measuring “box”, and later go back to the same site, extract the data from the box to a USB-stick and then putting the USB-stick into a PC where the data collected data was manually analyzed.

The solution: A modern and connected industrial IoT solution powered by Azure

We set out to replace this inefficient manual process with a connected, Azure-powered, data- and event-driven industrial IoT solution, that provides detailed real-time insights and analysis about the concrete mix, from the comfort of the office. It also enabled additional value-adding features such as forecasts based on ambient site temperature.

To bring real-time monitoring to life, we deployed wireless IoT sensors in specific combinations that measure the concrete’s strength as it’s curing.

Setting the foundation: Planning, Requirement Gathering, and Success Factors

Truth be told, the majority of IoT projects fail, and many never even leave the experimentation phase. This happens when the data- and solution architecture isn’t designed for the particular use case that a specific workload calls for. Our holistic approach was tailored to address Thomas Concrete Group’s and their customers’ specific needs and is a big reason that the company was able to gain a competitive advantage in the industry. Digitalization alone does not translate to success – it has to be done right.

The first step for Axelsson Consulting in developing an IoT solution to remotely collect, store and compute the material strength for Thomas Concrete Group was to identify key success factors. This would allow us to avoid pitfalls and unlock the full digital business potential of IoT as it relates to this particular use case. After this vetting process, we created a solution proposal that outlined our recommendations for sensors, connectivity, data requirements, storage, device management, application and communication protocols, edge architecture, including offline capability in case of temporary connectivity loss, IoT platform, and modules. From there, we were able to accurately predict the power consumption and expected battery life, and overall cost.

Once we decided on the technical aspects together with Thomas Concrete Group’s IT department, it was time to implement the solution. Here, we designed the software and hardware architecture so that it fulfills the business use case in real life. For this particular application, we made full and best practice use of Azure EventHub, serverless Azure Functions, Azure Kubernetes Service, Azure Premium SSD Managed Disks, Crate DB for time series data, as well as Azure DevOps for continuous integration and deployment, and Azure Cosmos DB for unified business data, including order, product, project and recipe data.

Azure IoT Hub played a pivotal role in the sensor architecture and was used for device management, event-driven data ingestion of sensor data in the cloud-native sensor architecture, as well as for sending cloud-to-device messages, such as firmware instructions enabling or disabling certain device features when needed, such as triggers, to ensure compliance so that the number of messages, typically 140 transmitted uplink messages per day, do not trespass the regulatory limit within the ISM band in which both SigFox and LoRaWAN operate, which mandates that the maximum mean transmission time should not exceed 1% of the network bandwidth.

In the early experimentation phase, connectivity tests were conducted to validate if the public IoT infrastructure would be enough or not to ensure. Selecting a dedicated IoT communication protocol and network became an easy choice and was based on the known inherent advantages of low-frequency radio communication that also showed in real-life tests, such as long battery life and the ability to penetrate obstacles like walls and ceilings, unlike high-frequency cellular networks such as 4G/LTE and 5G that sacrifices battery life and range for high data transfer speeds. The tests we conducted together with the client showed that the inherent advantages of IoT networks, like long battery life, were certainly there, but also that a local gateway should preferably be used, e.g., at a central place such as an office at the project site, to ensure the best possible results and coverage for the end users, a good fit for both SigFox and LoRaWAN anyway, as packets are broadcast to all visible gateways.

Working together with the client, it was also during this time and following requirement gathering, that it was decided that both SigFox and LoRaWAN communication protocols should be supported by the connected solution, and that a hardware vendor should be selected, preferably already manufacturing both 868 MHz for European markets and 433 MHz certified sensor devices for the upcoming North-American launch, and that the same cloud architecture should useable in a streamlined and unified manner for all markets with minimal or no additional modification to the architecture.

How we built a resilient and data-driven cloud-native IoT solution in Azure

Throughout the implementation process, we validated how the solution and architecture behaved and performed. This allowed us to make adjustments where necessary and ensure functionality and security end-to-end.

Real-life tests of the solution took place in Thomas Concrete Group’s wholly owned and accredited laboratory for material testing, and research and development. The tests included monitoring concrete poured into cubes using both the IoT sensors, and cables, in the new connected solution, as well as the legacy, and tried, solution connected to the offline “box”, to validate, and later sign off the results.

An important aspect for the end-user in the new solution was to be able to select the appropriate project, order, and order row product from the ERP. It was clear that the existing pull-based solution for unified data leveraging Azure Data Factory with Azure Data Bricks for data transformation, would not be acceptable, a real-time integration was needed. We leveraged Azure Integration Services, Azure Logic Apps, Azure Integration Accounts, and Azure Functions to implement an event-driven and serverless enterprise integration for ingesting order data from the ERP in real-time, thus making orders, and their products, selectable in the presentation layer, seconds or less after having been created in the source system.

Another requirement was for the end users to download reports in PDF format of completed measurements, including strength development curves, the material temperature during the course of measurement, and more, in multiple languages in a pdf. Creating dynamic PDFs can many times be a chore, and be especially tricky when highly stylized. For this case, we adopted using a virtual Razor view engine rendering the content based on .cshtml view templates in-memory before converting it into a pdf byte array, benefits being a strongly typed (virtual) frontend, as well as regular HTML, CSS and JS used for rendering the pdf layout also in the backend, which enabled partial re-use of the existing code used for visualizing the results in the frontend while ensuring that the languages used across supported markets were rendered as expected.

Together with the client, Axelsson Consulting also discussed and implemented a new way to charge for the benefits of the new digital services. A subscription model was implemented where different tiers give access to certain sets of features, with validation taking place in an ASP.NET Core Middleware, preventing requests before they reach the API controller unless they have been made by a customer with the appropriate access and subscription tier to access the requested feature.

Delivering on a tight deadline and despite a high failure rate

Axelsson Consulting was tasked with delivering a market-ready solution by the beginning of the following year, with the decisive green light for the implementation phase commencing just five months before that. Of course, we knew full well that the majority of IoT projects fail to progress from proof-of-concept to tangible business value in production. But with our expertise in the technologies at hand and a methodology with a proven track record of success – having already led the completion of the real-time asset tracking solution previously – we were confident in getting the job done on time.

With a short amount of time given the rather extensive scope, including IoT testing, implementation and validation, REST API design, extensive software engineering and modernization of the decades-old legacy software, as well as frontend and presentation layer development, and given the size of the Axelsson Consulting team at the time, consisting of one Sr. Solution Architect / Backend Engineer, one Sr. Frontend Engineer, and one Backend Engineer respectively, we quickly realized we needed to ensure bottlenecks were kept to an absolute minimum to be able to deliver the project to market at the desired time, and that we needed quick and prompt feedback continuously on deliverables in the testing environments. Thankfully, the time and effort were put in by all parties to make the project a success, including the PO.

We realized that quick and prompt communication with the lab was also needed and that we did not always speak the same language. Keeping things simple, we created a shared Excel file from which we validated and test the modernized curing algorithm. It may seem simple, but Excel was a common denominator that both engineers and lab experts talked and understood, speeding up the testing and implementation phase.

How we helped the client gain a new competitive advantage

The digital modern cloud-native industrial IoT solution delivered by the Axelsson Consulting team for Thomas Concrete Group, digitalized a highly manual process with a modern, cloud-powered and connected solution, unlocking new digital insights for their customers, allowing them to build better and faster, while profoundly improving its business and service offering to its customers, as well as enabling new digital business models for the client – on time, within budget, and ready to scale.

Now, Thomas Concrete Group’s customers can get precise data-driven insights on the progression and state of their construction projects remotely, made possible by the right use of cloud-native services and products in Azure and IoT networks, anytime and anywhere, allowing builders to reduce wasteful time and proceed without delay, saving time and money.

It’s a win-win: Thomas Concrete Group is enabling its customers to operate more efficiently than ever through digital technologies – a significant competitive advantage in a slow-moving industry.

Just as in our Real-Time Asset Tracking solution, CrateDB was used as an integral part of the architecture for storing semi-structured sensor data. You can read more about how we used the database for this particular industrial IoT case study here.

Following the launch of the solution across European markets, the North-American news outlet Enterprise IoT Insights also covered how digital-, cloud-, and IoT technologies were used to digitalize business processes and supply chains, you can read more here.

IoT connectivity and solutions are all about achieving more with less, which, in addition to efficiency gains, will be crucial to meeting sustainability goals, as we approach 2030. Looking to learn more? Subscribe to our newsletter to get our expert insights, as well as upcoming case studies, straight to your inbox.

122%

122%

122%

Challenge

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris ullamcorper ultrices volutpat. Mauris ac neque sed ante placerat molestie et a est. Sed aliquam felis tempus, cursus arcu eu, ultricies dolor...

Actions

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris ullamcorper ultrices volutpat. Mauris ac neque sed ante placerat molestie et a est. Sed aliquam felis tempus, cursus arcu eu, ultricies dolor...

Results

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Mauris ullamcorper ultrices volutpat. Mauris ac neque sed ante placerat molestie et a est. Sed aliquam felis tempus, cursus arcu eu, ultricies dolor...

Project Timeline

-

Lorem ipsum dolor sit amet

-

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur mattis neque consectetur, congue sapien quis, egestas magna. Fusce eget nulla vel dolor dictum aliquet. Duis urna diam, pellentesque non erat vel, finibus porttitor ex. Maecenas ac metus lacus. Nulla facilisi. Duis lorem mi, vestibulum ullamcorper ex a, iaculis vestibulum purus. Donec ultrices placerat turpis ut efficitur. Donec ut nisl pharetra, convallis diam a, ornare tellus. Pellentesque vel convallis dolor, id pellentesque augue. Cras neque nibh, cursus non erat nec, rutrum hendrerit turpis. Ut a lectus tincidunt, fringilla nibh non, consequat diam. Nam elementum semper malesuada. Ut efficitur purus in arcu ullamcorper, a bibendum est efficitur. Vivamus et nulla fermentum, vulputate sem vitae, ullamcorper est. Praesent consequat ante et ante fringilla, sit amet vehicula nisi rhoncus.

-

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur mattis neque consectetur, congue sapien quis, egestas magna. Fusce eget nulla vel dolor dictum aliquet. Duis urna diam, pellentesque non erat vel, finibus porttitor ex. Maecenas ac metus lacus. Nulla facilisi. Duis lorem mi, vestibulum ullamcorper ex a, iaculis vestibulum purus. Donec ultrices placerat turpis ut efficitur. Donec ut nisl pharetra, convallis diam a, ornare tellus. Pellentesque vel convallis dolor, id pellentesque augue. Cras neque nibh, cursus non erat nec, rutrum hendrerit turpis. Ut a lectus tincidunt, fringilla nibh non, consequat diam. Nam elementum semper malesuada. Ut efficitur purus in arcu ullamcorper, a bibendum est efficitur. Vivamus et nulla fermentum, vulputate sem vitae, ullamcorper est. Praesent consequat ante et ante fringilla, sit amet vehicula nisi rhoncus.

-

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur mattis neque consectetur, congue sapien quis, egestas magna. Fusce eget nulla vel dolor dictum aliquet. Duis urna diam, pellentesque non erat vel, finibus porttitor ex. Maecenas ac metus lacus. Nulla facilisi. Duis lorem mi, vestibulum ullamcorper ex a, iaculis vestibulum purus. Donec ultrices placerat turpis ut efficitur. Donec ut nisl pharetra, convallis diam a, ornare tellus. Pellentesque vel convallis dolor, id pellentesque augue. Cras neque nibh, cursus non erat nec, rutrum hendrerit turpis. Ut a lectus tincidunt, fringilla nibh non, consequat diam. Nam elementum semper malesuada. Ut efficitur purus in arcu ullamcorper, a bibendum est efficitur. Vivamus et nulla fermentum, vulputate sem vitae, ullamcorper est. Praesent consequat ante et ante fringilla, sit amet vehicula nisi rhoncus.

-

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur mattis neque consectetur, congue sapien quis, egestas magna. Fusce eget nulla vel dolor dictum aliquet. Duis urna diam, pellentesque non erat vel, finibus porttitor ex. Maecenas ac metus lacus. Nulla facilisi. Duis lorem mi, vestibulum ullamcorper ex a, iaculis vestibulum purus. Donec ultrices placerat turpis ut efficitur. Donec ut nisl pharetra, convallis diam a, ornare tellus. Pellentesque vel convallis dolor, id pellentesque augue. Cras neque nibh, cursus non erat nec, rutrum hendrerit turpis. Ut a lectus tincidunt, fringilla nibh non, consequat diam. Nam elementum semper malesuada. Ut efficitur purus in arcu ullamcorper, a bibendum est efficitur. Vivamus et nulla fermentum, vulputate sem vitae, ullamcorper est. Praesent consequat ante et ante fringilla, sit amet vehicula nisi rhoncus.

-

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur mattis neque consectetur, congue sapien quis, egestas magna. Fusce eget nulla vel dolor dictum aliquet. Duis urna diam, pellentesque non erat vel, finibus porttitor ex. Maecenas ac metus lacus. Nulla facilisi. Duis lorem mi, vestibulum ullamcorper ex a, iaculis vestibulum purus. Donec ultrices placerat turpis ut efficitur. Donec ut nisl pharetra, convallis diam a, ornare tellus. Pellentesque vel convallis dolor, id pellentesque augue. Cras neque nibh, cursus non erat nec, rutrum hendrerit turpis. Ut a lectus tincidunt, fringilla nibh non, consequat diam. Nam elementum semper malesuada. Ut efficitur purus in arcu ullamcorper, a bibendum est efficitur. Vivamus et nulla fermentum, vulputate sem vitae, ullamcorper est. Praesent consequat ante et ante fringilla, sit amet vehicula nisi rhoncus.

Do you want to know more on our industrial IoT services?

Click the button below to learn more on how we can help you deliver more business value through IoT and cloud native technologies

Contact

Interested to know more?

Send us a message and let’s chat. We can walk you through our core offerings and how by working with us you can scale your business.

Contact